FAILURE ANALYSIS

Since its inception of Neo Phoenix Testing and Consultancy Services (2015) have completed more than 500 industrial component failure analysis assignments from a variety of industries including Automotives, Biomedical, Textile mill, Pharmaceutical, Off-way vehicle industries, Oil & Gas industries. We review such assignments under the mentorship of an eminent metallurgist.

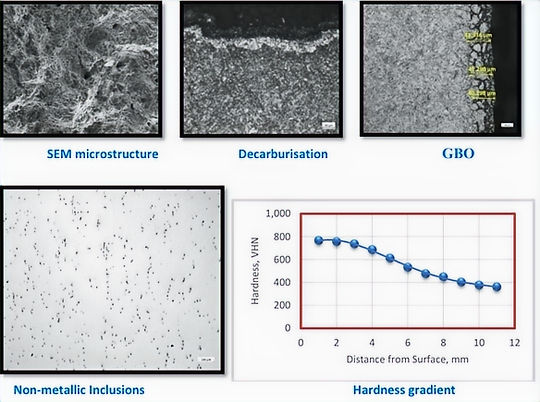

Understanding why a component failed is important for several reasons. First, a determination of the mode of damage responsible for the failure is an essential component of any root cause analysis, although in most cases it is not sufficient for identifying the root cause of failure. Second, understanding a component failure provides essential information for preventing additional or similar failures, as well as ensuring appropriate repair or replacement decisions are made. Perhaps most importantly, an erroneous or incomplete analysis can be worse than no analysis at all, since this can prompt inappropriate responses that do not address the basic cause of failure or even increase the potential for additional failures. The degrees to which a failure analysis can be applied range from simply determining the failure mode to performing a full root cause analysis of the failure event. For each situation that occurs, the approach required should be evaluated to determine the level of metallurgical evaluation or engineering effort that should be expended. Identifying the mode of a failure can range from relying on a thorough visual examination by a competent failure analyst to a full laboratory analysis consisting of some or all of the following tasks- such as Visual examination, NDT, Chemical composition, Microstructural analysis by Optical microscope and SEM, Hardness analysis / mechanical properties, Fractography, Characterization of elements by ICP, gas content analysis, residual stress analysis, etc.